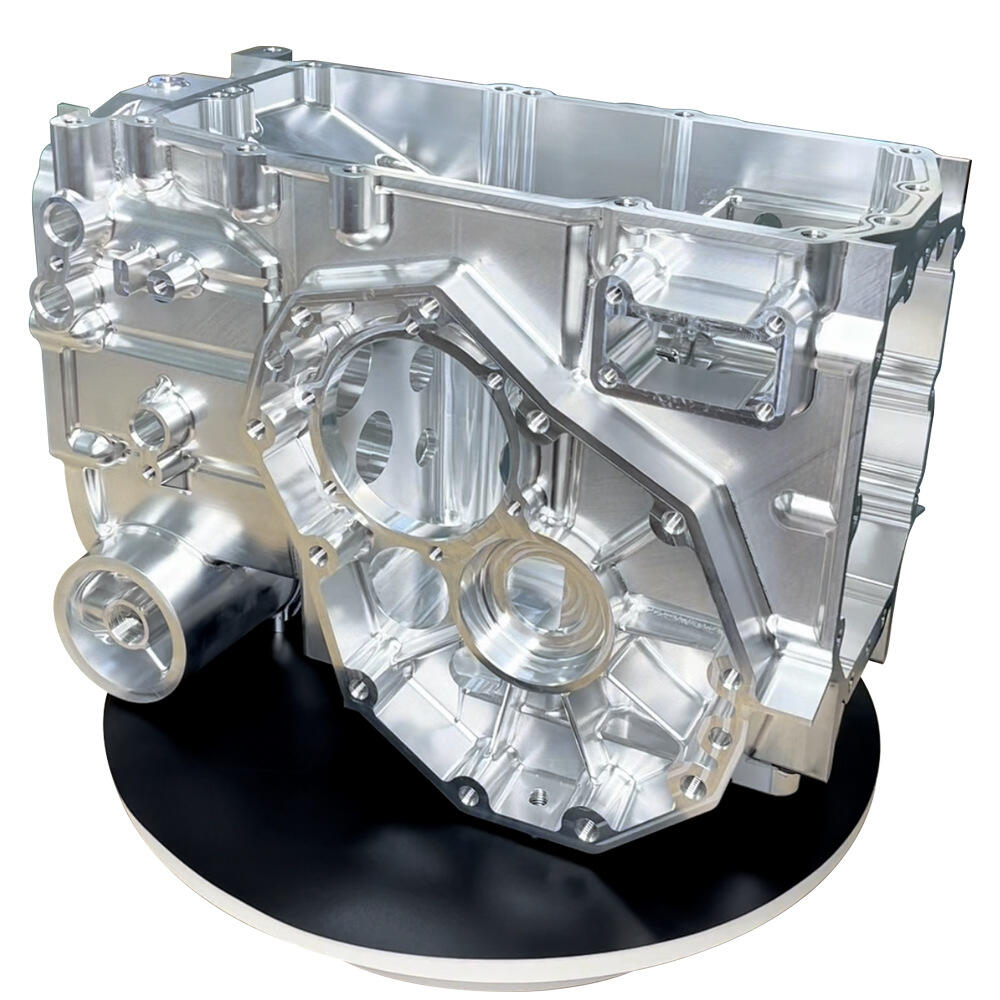

Sino Rise's 5-axis machining services provide unparalleled speed and flexibility. Equipped with a wide variety of advanced 5-axis CNC machines and a diverse selection of materials, Sino Rise is capable of producing top-notch 5-axis machined parts. Our seasoned team and robust manufacturing capabilities enable the rapid design and fabrication of intricate and time-critical components. With world-class equipment, professional expertise, and rich experience, Sino Rise employs two excellent setups to manufacture precise and complex parts.

In addition to the three linear axes of X, Y, and Z, it also has two rotary axes. Commonly, the rotary axes are the A-axis (rotating around the X-axis), the B-axis (rotating around the Y-axis), or the C-axis (rotating around the Z-axis). This enables the cutting tool to adjust its posture at any angle in space, making it possible to machine parts with complex curved surfaces, such as aero-engine blades, impellers, molds, etc.

It can machine multiple surfaces in a single clamping, reducing the number of clamping operations. Consequently, it decreases the accuracy loss caused by clamping errors. Meanwhile, it significantly shortens the machining time and improves the overall machining efficiency.

| Description | |

|---|---|

| Aluminum | AL6061/ AL5052/ AL2024/ AL7075/ AL5083/ ADC12/ AL6082 |

| Stainless Steel | SUS301/ SUS303/ SUS304/ SUS316/ SUS316L/ SUS420/ SUS430/ SUS630/17-4PH/ SUS321 |

| Alloy Steel | Q235(A3Steel/ C45/ Cr12/ 3Cr13/ GCr15/ 40Cr/ 65Mn/ SKD11/ Steel 1018/ Steel 1020/

High speed steel/ Cold rolled steel/ Bearing steel/ SPCC |

| Stainless Steel | SUS301/ SUS303/ SUS304/ SUS316/ SUS316L/ SUS420/ SUS430/ SUS630/17-4PH/ SUS321 |

| Copper Alloy | H59/ H62/ H68/ H80/ Tin Bronze/ C17200/ Aluminum Bronze |

| Titanium | TA1/ TC4 |

| Plastic | ABS/ PTFE/ POM/ Bakelite/ PMMA/ PP/ PPS/ FR4/ HDPE/ LDPE/ PA6/ PA66/ PC/ PVC/ PU/ PEEK/

|

| Special Materials and Others | Carbon Fiber /Glass Fiber |

Machining Capabilities Our ISO 9001 certification shows that we fabricate 5-axis milled parts to meet the tightest tolerance requirements. Our standard tolerance for CNC-milled plastics is ISO-2768-m and ISO-2768-f for metals. Get high-quality and precise complex parts with top-notch dimensional stability.

| Description | |

|---|---|

| Maximum Part Size | 4000×1500×600 mm |

| Minimum Part Size | 5 x 5 x 5 mm |

| General Tolerances | Within ±0.002 mm |

| Lead Time | For standard operations, lead times can be as short as 2-3 days, while more complex projects might require up to 2 weeks. |

Yes, 5-axis CNC machining is renowned for its ability to achieve exceptionally tight tolerances. It can typically maintain precision within ±0.005 mm. This high level of accuracy is due to the machine’s capability to access five sides of a part in a single setup, reducing the number of setups required and minimizing errors associated with repositioning. The simultaneous movement along five axes allows for closer tool paths, ensuring precise adherence to design specifications, especially for complex geometries.

pt for 5-axis CNC machining when manufacturing parts with complex geometries, intricate details, or when high precision is critical. This technology is ideal for parts that require machining from multiple sides in a single setup or where multiple tool angles are necessary to achieve the design. Industries such as aerospace, medical, and automotive, where the geometrical complexities and tight tolerances are common, significantly benefit from 5-axis machining. It is also preferable when aiming to reduce lead times and improve surface finishes without compromising on detail.

The cost of 5-axis CNC milling services can vary widely based on several factors such as the complexity of the part, the type of material used, and the required precision. Generally, prices might range from $75 to $250 per hour depending on these variables. For a specific quote, it’s best to provide detailed drawings and specify material requirements on RapidDirect online platform so that a more accurate estimation can be calculated. Remember, while 5-axis machining might have a higher hourly rate, it often reduces the total production time and number of setups needed.

The main difference between 5-axis and 3-axis machining lies in their respective capabilities and the complexity of parts they can handle. 3-axis machining operates along three axes (X, Y, and Z), suitable for parts with relatively simple geometries. It typically requires multiple setups and repositioning to reach all sides of the part. Conversely, 5-axis machining adds two additional rotational axes, allowing the cutting tool to approach the part from virtually any direction. This capability makes it ideal for complex shapes, reducing setup times and improving precision by minimizing handling.