Rapid prototyping swiftly transforms initial design concepts into tangible models. It provides an expeditious and cost-efficient means to materialize ideas in the real world. Technologies like 3D printing, CNC machining, and others are especially effective in this regard. Usually, prototypes can be produced and delivered within a span of 1–3 business days. Choosing to engage in prototyping is crucial for accelerating the design process. Simultaneously, it mitigates the financial and operational risks linked to new product development. It allows for comprehensive testing and refinement of designs, guaranteeing that each successive iteration is an enhancement over the previous one. This process plays a vital role in enabling well-informed decisions at an early stage of the development cycle, thus minimizing the likelihood of costly modifications further along the line. Rapid prototyping rapidly turns early-stage design ideas into physical prototypes, presenting a quick and affordable way to visualize concepts. By leveraging technologies such as 3D printing, CNC machining, etc., it can generally deliver prototypes within 1–3 working days.

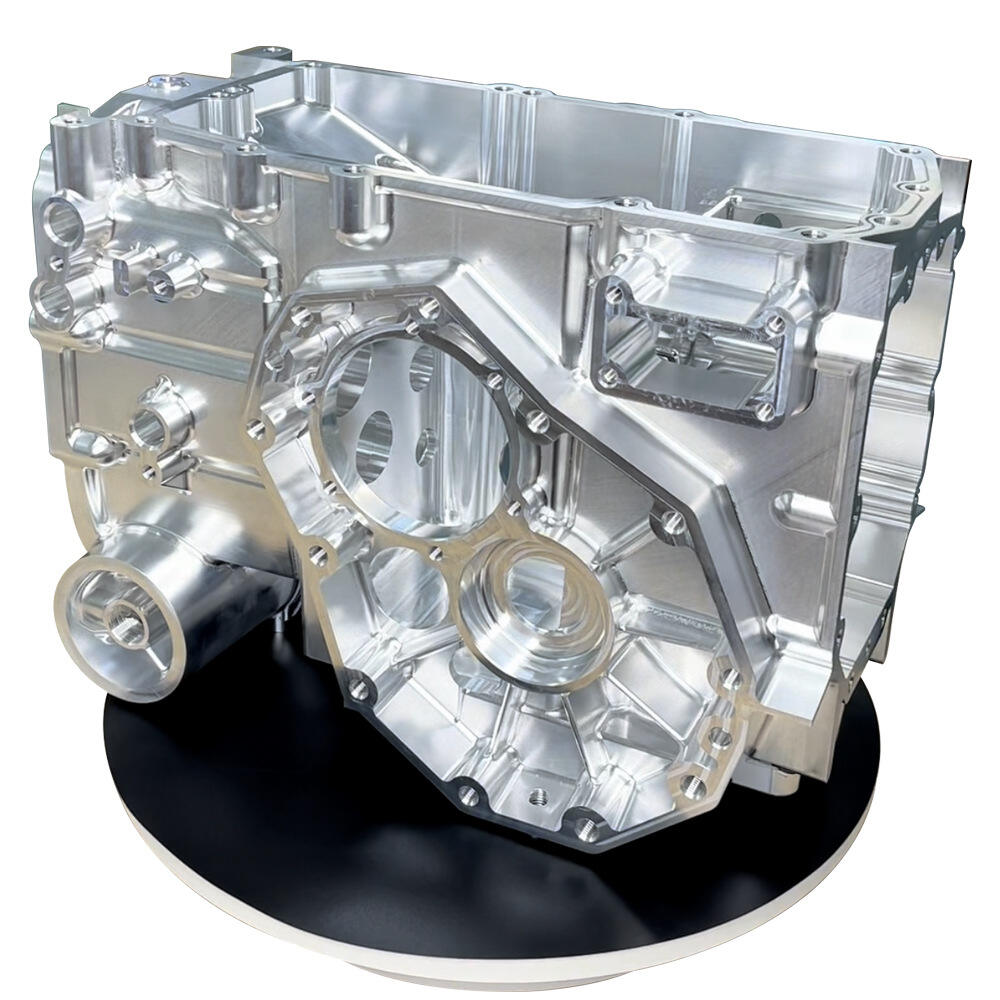

CNC machining stands as an excellent choice for rapid prototyping. It crafts precise and durable models using the actual final material. At Sinorise we are experts in machining both metals and plastics. Our proficiency allows us to rapidly produce high - quality prototypes, frequently within just 1 day. We offer a range of advantages. Our in - depth expertise ensures top - notch results. With our precise expedite options, we can meet tight schedules. Moreover, our pricing is affordable, making it easier to support the rapid development of products. Regarding part sizes, for CNC Milling, the maximum dimensions are 4000×1500×600 mm, and for CNC Turning, it's 200×500 mm. Our standard lead time is an impressively short 1 day, and we maintain a high - precision tolerance of 0.001 inches.

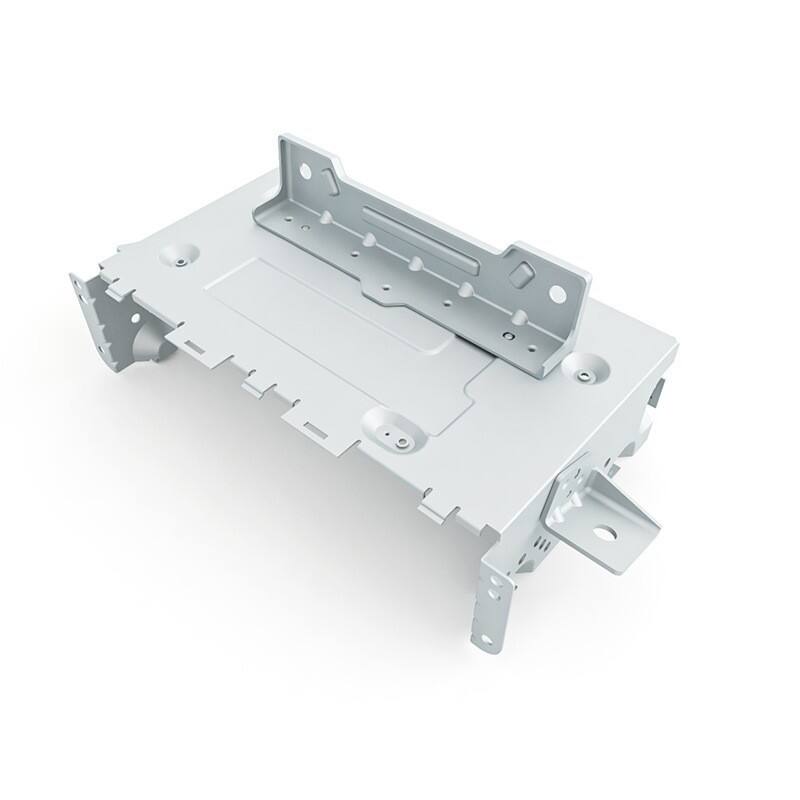

Sheet metal fabrication is an efficient process that can swiftly generate flat components in their final metal state, typically within a week. It is cost - efficient and adaptable to a wide array of designs. At Sinorise, we provide a diverse selection of alloys, enabling us to deliver high - quality prototypes without delay. Our sheet metal fabrication services come with several notable features. We achieve cutting accuracy within ±0.2mm and a bend angle accuracy of ±1.0°. The standard lead time for our services is a short 1 - 2 days. In terms of tolerances, we generally adhere to the ISO 2768 - c standard. This ensures that all fabricated parts meet the required precision and quality benchmarks, making us a reliable choice for all your sheet metal fabrication needs.

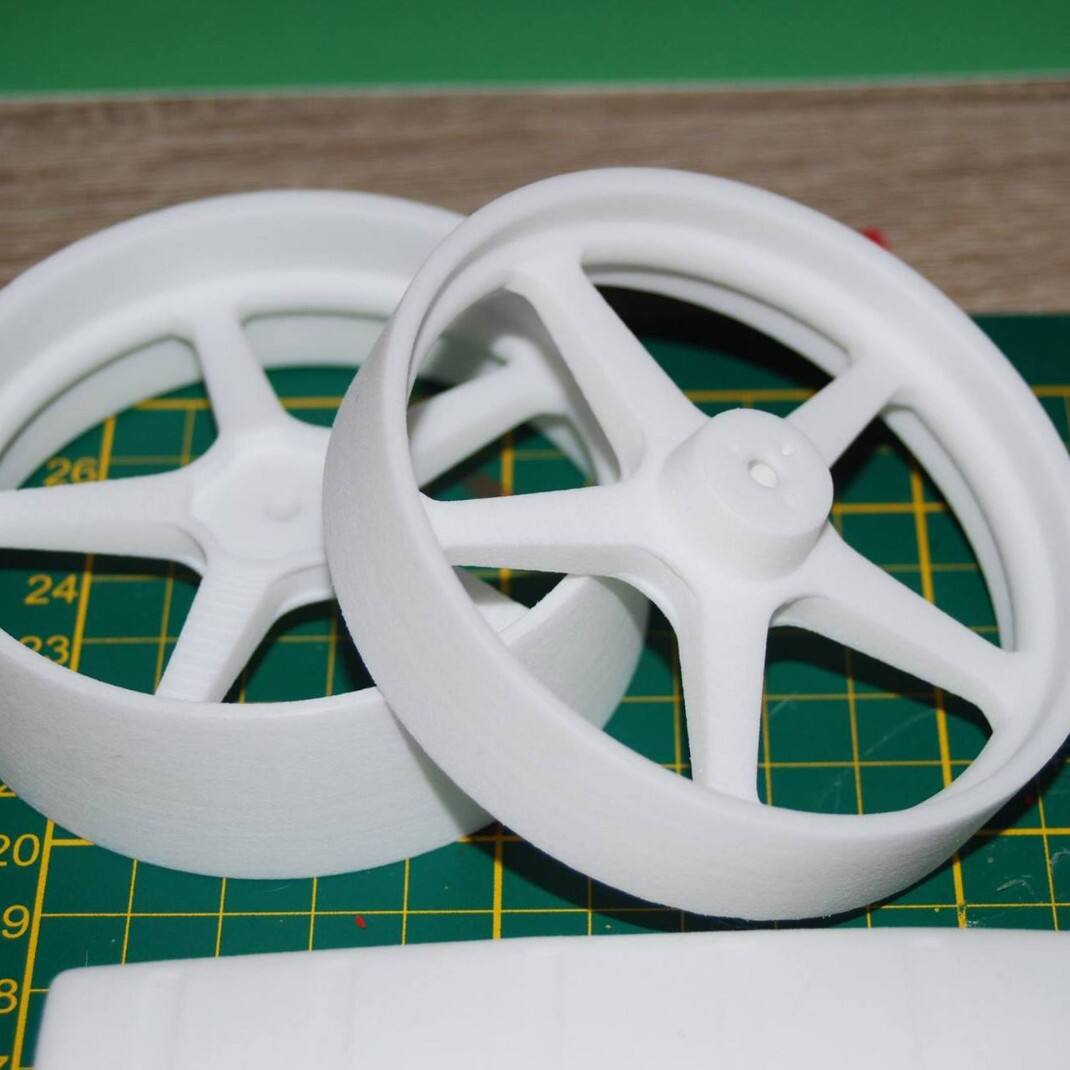

3D printing excels in rapid prototyping, delivering quick, cost-effective models often in a day. Methods include SLS for versatility, SLA for fine finish and accuracy, and FDM for large parts. Sinorise offers expertise and advanced 3D printing, ensuring high-quality parts. Max. build size: 1400x700x500mm. Standard lead time: 4-6 days. Dimension tolerance: ±0.2mm (0.15% for >100mm).

Vacuum casting offers high-quality, detailed replicas quickly and cost-effectively. Sinorise ensures fast delivery and high fidelity in prototypes, with versatile materials and finishing options. Max part size: 0.025m. Standard lead time: up to 20 parts in 15 days. Tolerance: ±0.05mm.

| Advantages | Disadvantages | |

|---|---|---|

| Rapid CNC Machining | High precision and suitability for a variety of materials. Ideal for functional and durable parts. | Higher cost and longer lead times compared to some additive manufacturing processes. |

| Rapid Injection Molding | Excellent for high-volume production. Provides end-use, functional parts with fine details. | Upfront costs for molds are high, less economical for small quantities. |

| Rapid Sheet Metal Fabrcation | Good for durable prototypes, allows quick modifications. Suitable for both prototyping and production. | Limited complexity, not ideal for intricate designs requiring high detail. |

| Rapid 3D Printing | Fast and cost-effective. Capable of complex geometries that are not possible with other methods. | Material properties might not match those of traditionally manufactured parts. Resolution varies by technology. |

| Rapid Vacuum Casting | Suitable for producing small quantities of highly detailed replicas quickly and affordably. | Generally used for non-functional prototypes or visual models due to material properties. |

Rapid prototyping turns early-stage design ideas into physical models quickly and cost-effectively.

Prototypes can typically be delivered within 1-3 business days.

It allows for thorough testing and refinement, ensuring improved designs each iteration.

Technologies include 3D printing, CNC machining, and others.

It speeds up the design process and reduces risks in new product development.

Early in the development cycle to make informed decisions and minimize later alterations.