Sino Rise offers premium sheet metal fabrication services, specializing in the production of durable and long-lasting manufactured parts and prototypes using metals and alloys. Whether you require a one-off prototype or thousands of identical parts, we are fully equipped to serve you. With advanced processes and exceptional craftsmanship, we ensure each component meets precise cutting, bending, and design specifications.

Sheet Metal Fabrication Services specialize in creating custom parts tailored to your specifications, utilizing a range of metals and alloys to ensure durability and precision in every component.

We have high accuracy laser cutting machines inhouse from China and be able to cut steel materialthickness up to 20mm with high tolerance.

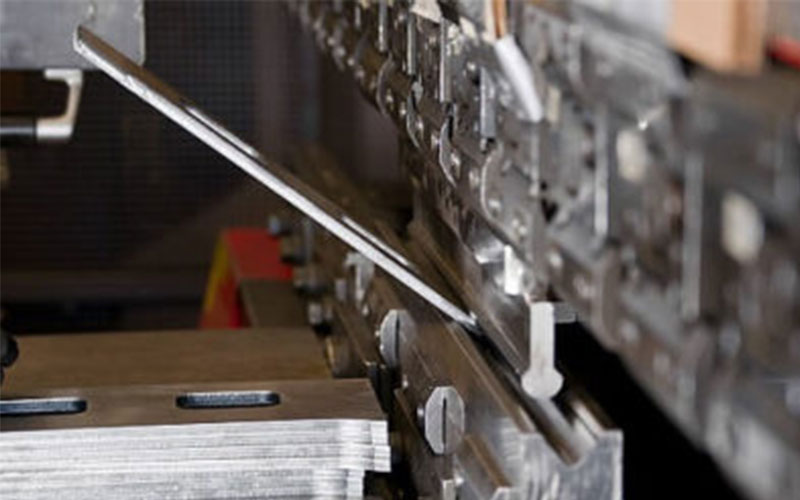

We have a high level of CNC bending manufacturingability in China. With our full range of standard CNCpress brake tooling, we are able to make all kinds ofbending processes.

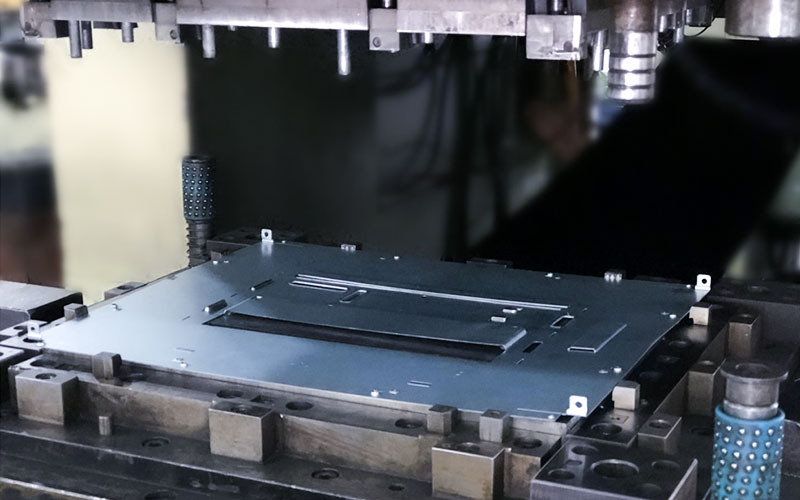

Also called pressing ,placing flat sheet metal, in eithercoil or blank form, into a stamping press. In the press, atool and die surface form the metal into the desiredshape. Punching, blanking, bending, coining.embossing, and flanging are all stamping techniquesused to shape the metal.

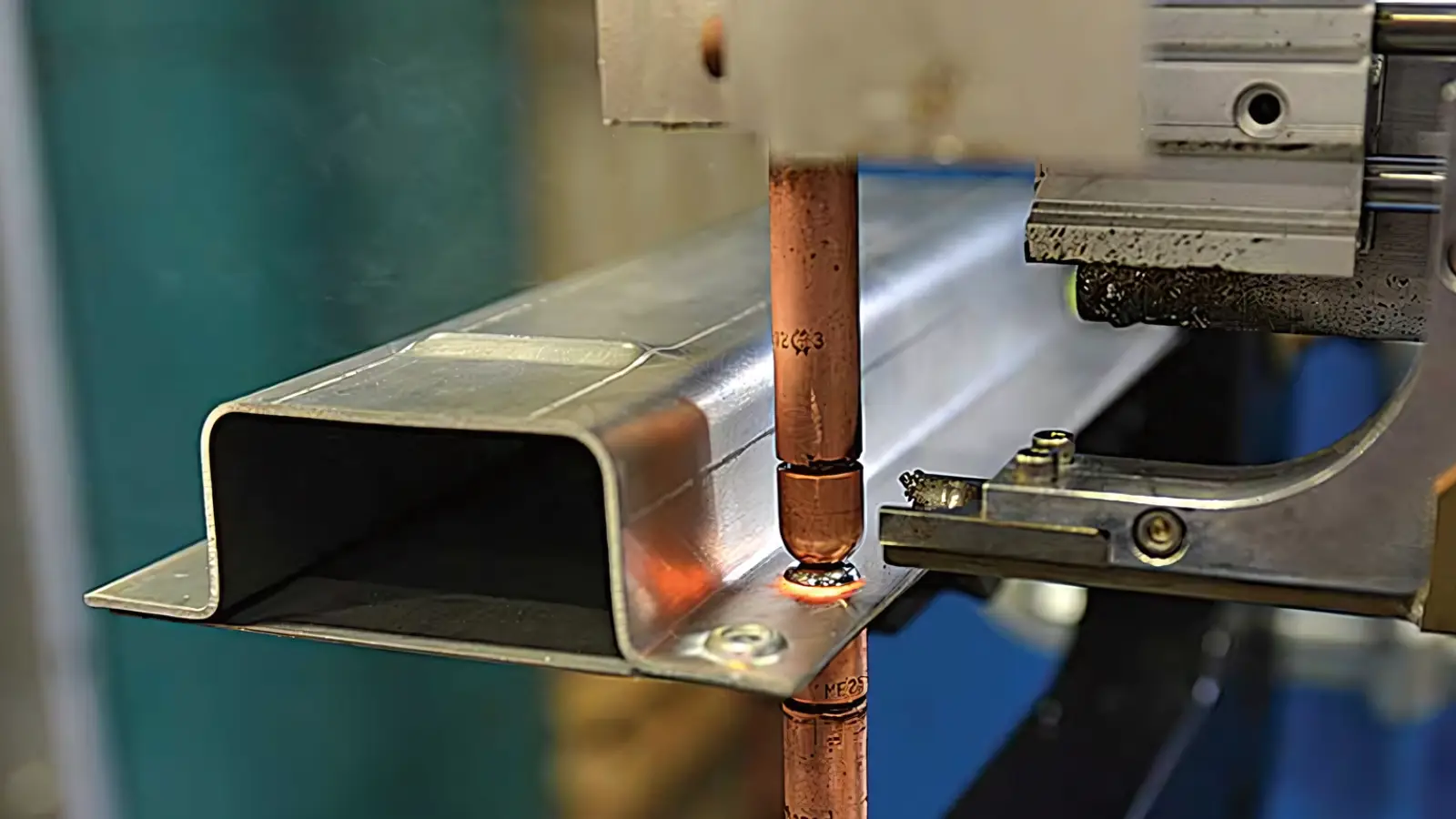

Welding serves as a method for uniting two or more metal components. This is accomplished by means of heat, pressure, or a combination of the two, resulting in a robust connection. It demands a blend of expertise and exactitude to fabricate long - lasting and robust metal frameworks.

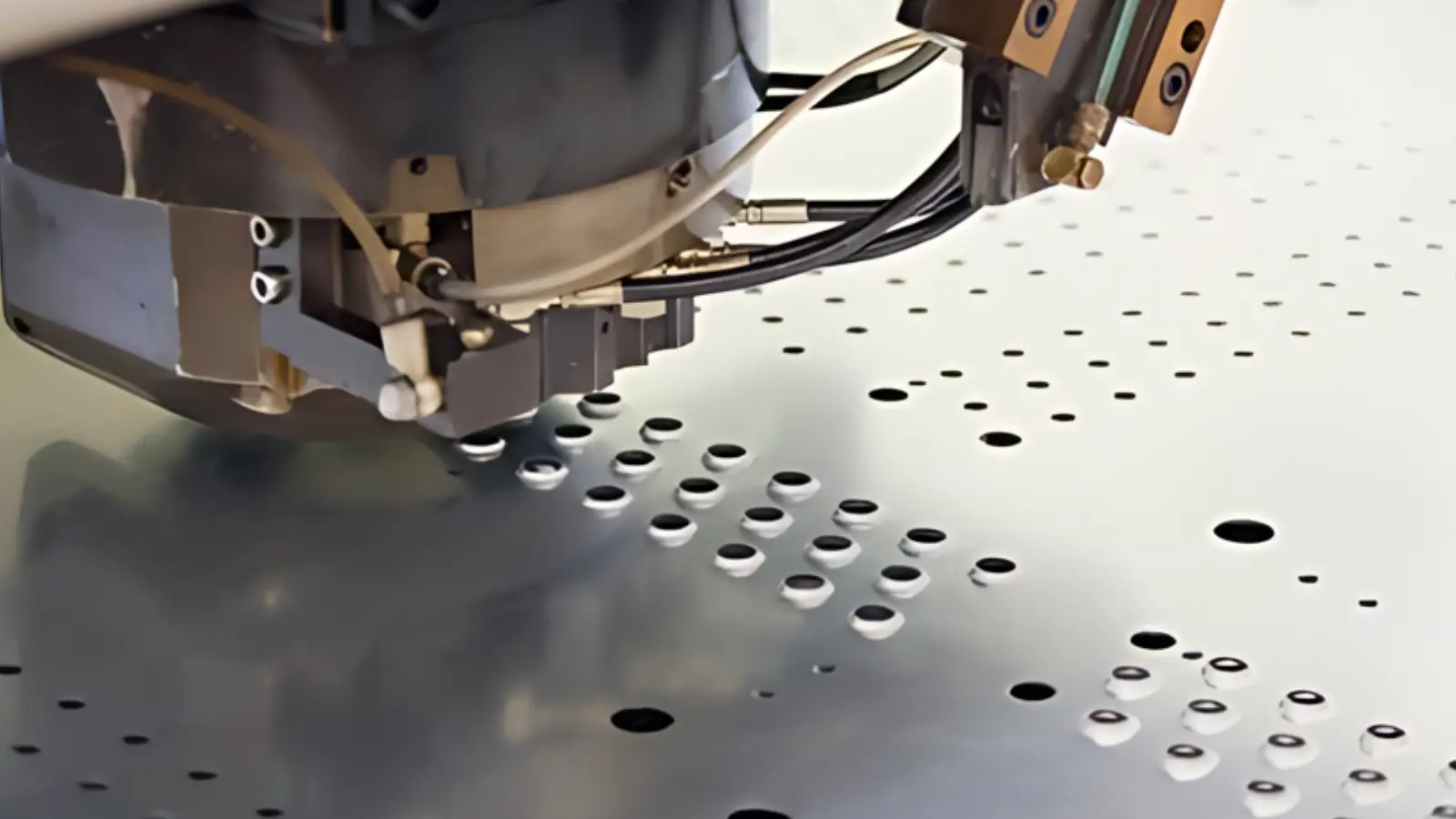

In the process of punching, a punch tool is utilized. It is pushed through a die, and by means of a shearing action, it cuts the metal to create holes or shapes. This method ensures precise and clean outcomes in the fabrication process.

Riveting functions as a semi - permanent technique for joining. Mechanical fasteners known as rivets are employed to link sheet metal components. Compared to welding, it offers the advantages of being quicker and significantly more cost - efficient.

| Hole sizes | +0.005 |

| Edge to edge, single surface | ±0.010 |

| Edge to hole single surface | ±0.010 |

| Hole to hole, single surface | ±0.005 |

| Bend to edge / hole, single surface | ±0,015 |

| Bend to bend | ±0.020 |

| Edge to feature, multiple surface | ±0.030 /> |

| Over formed part, multiple surface | ±0.030 |

Starting a sheet metal project is straightforward and efficient with SinoRise. First, prepare a detailed design of your part or component. If you’re unsure about the specifications, our team of experienced engineers is ready to assist you in optimizing your design for fabrication. Next, upload your design files directly to our online quoting system. Here, you can easily configure part specifications such as material selection, thickness, and finishing options. Once submitted, you will receive a customized quote based on your project’s requirements. After you approve the quote, we’ll begin the fabrication process. Our advanced machinery and skilled technicians ensure precision and quality. You’ll be updated throughout the process, from manufacturing to the final delivery of your parts.

The cost of sheet metal fabrication varies widely based on several factors including the complexity of the parts, the type of material used, the quantity of parts, and the specific fabrication processes required. For straightforward, simple parts, the cost can be quite competitive, especially when leveraging our efficient production techniques and advanced machinery. To get a specific cost estimate, we encourage you to use our easy-to-use online quoting system. Here, you can upload your design files, select materials, specify quantities, and choose finishing options. Our system will provide you with a detailed quote reflecting the precise cost of your project. For larger or more complex orders, costs will adjust based on additional processing and labor required. Our goal is always to offer the best value, combining cost-effectiveness with high-quality results.

The lead time for receiving your custom sheet metal parts depends on several factors including the complexity of the parts, the quantity ordered, and the specific fabrication processes required. For simple parts, we can often deliver within as little as 3 days from the time your order is placed and the design is confirmed. For more complex assemblies or larger volumes, the production time will be extended accordingly. Once you submit your design through our online quoting system, we provide an estimated delivery timeline along with your quote. This estimate takes into account the current workload in our fabrication facilities and the specific requirements of your project. We strive to minimize turnaround time without compromising on quality, ensuring you receive your parts as quickly as possible while maintaining the highest standards of fabrication.

At SinoRise we support projects of all sizes. We accommodate both small and large production runs, offering our services for everything from a single prototype to mass production. Importantly, we do not enforce a strict minimum order quantity. This flexibility allows customers, whether startups or large corporations, to leverage our sheet metal fabrication services tailored to their specific needs and scales